Types of Embossing and Dies

Blind Emboss: Blind emboss is embossing done on a substrate with no form of printing or marking in the embossed area. The colour of the embossed image is the same as the colour of the substrate. It is also known as self-emboss or same colour embossing (2D, 2½D or 3D die required).

Registered Emboss: An embossed image that exactly registers to a printed or foil stamped image. The printed image area is embossed to give it a raised look (2D, 2½D or 3D die required).

Single-Level Emboss: Embossing where the image area is raised to just one flat level (2D, 2½D required).

Multi-Level Emboss: Embossing where the image area is raised to multiple levels having different depths and angles. This gives the embossed image texture and added relief (3D die required).

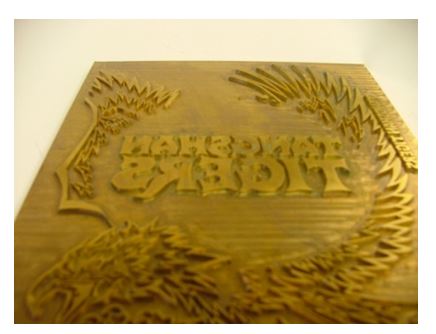

Sculptured Emboss: An embossing style originally referred to a hand chiselled engraving process. Now it is more often than not a CNC engraved die with occasional hand finishing. The process starts with a photograph or a drawing with various levels of depth to make the image appear realistic and multi-dimensional (3D die required).

Printed Emboss: A style where the substrate is first printed and then embossed in registration on the printed image. Depending on requirements a bevel can be included which can be either within the print image or outside (2D, 2½D or 3D die required).

Tint Emboss: This style involves the foil stamping and embossing of the image using pearl or pastel foil. Tint embossing is the same as other embossing but the use of pearl or pastel foil creates a unique and classy look. It is strongly recommended to use white stock for tint embossing because pearl and pastel foils are transparent (2D, 2½D or 3D die required).

Combo Emboss: This refers to an embossed image that is also foil stamped (2D, 2½D or 3D die required).

Glazing: Glazing is a technique where a mirror polished embossing die is used to blind emboss, using heat and pressure, to create unique effects particularly on dark coloured plain and textured substrates. When embossing, by substantially increasing the heat and pressure, you are able to add a shine (burnished effect) to the surface of a matte substrate. When embossing at very high temperatures, using light coloured paper or card, a scorched effect colour change will occur on the substrate. If done properly, this will create great contrasting effects and designs (2D, 2½D or 3D Die required).

Gloss Emboss: This is a technique of combining a clear foil (similar to varnish, but deeper) with blind embossing, producing a high-gloss embossed image.

Debossing: The surface is depressed instead of raised as in Embossing (2D, 2½D or 3D die required).

Single Level Embossing: Raises an image above the stock level, on a single level (2D / 2½D die required).

Single Level Debossing: Presses an image down into the substrate, on a single level (2D / 2½D die required).

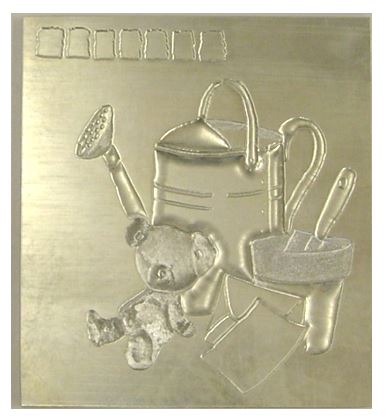

Multi-Level / Sculptured Embossing Dies: A realistic impression and illusion of a three dimensional image, for example a face (3D Die required).

Textured Embossing Dies: Textured embossing produces a tactile quality to embossing or foil stamping. Embossing and de-bossing techniques are great ways to add dimension and elegance to logos, images, headlines and other text. They can also be used to create texture and other realistic effects that mirror the printed design of a project. An extensive range of textured emboss effects can be created to enhance the background or be combined with other emboss images. Common textures are pebble or wood grain effect, but the list of effects that can be created are endless.

Duplicates: Phenolic or plastic duplicates taken from original engraved dies for use in place of, or alongside the original engraving. Duplicates are most commonly used when one image appears several times on the same master sheet.

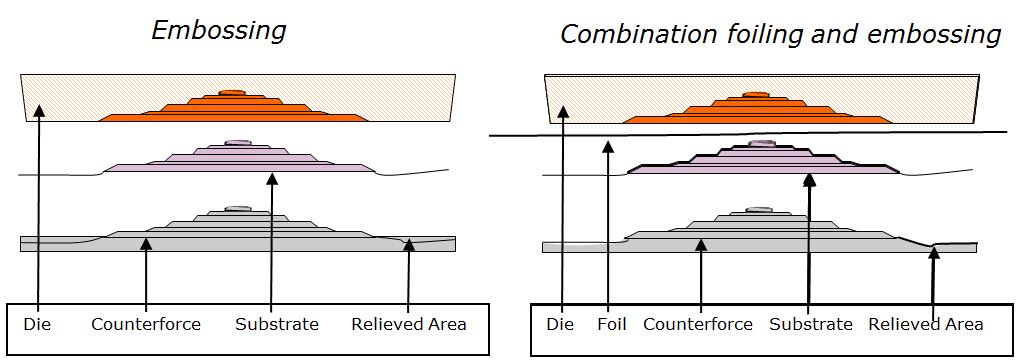

Combination Foil/Embossing

Engraving in metal allows you to create near photo quality multilevel or sculptured images.

CAD design software and CNC Engraving machines allow the designers to create elaborate designs accurately, consistently and quickly and at a relatively low cost. Advances in communications, electronics, software and automation have opened up all types of technology for the printing and allied industries. The manufacturing time and the cost of creating sculptured embossing or combination die is a fraction of what it once was. Not many years ago engravers were using a hammer and chisel to carve out intricate images for embossing, making engraving a very labour intensive, time consuming and expensive process. Though hand engraving still takes place, it is limited to specialist work or where programming on CAD-CAM software would take too long.

Examples of printed products including embossing can be seen everywhere from Greeting Cards, Book Covers, Business Cards, stationery, Cereal Boxes, Perfume Packaging, Presentation Folders and much more all use sculptured embossing and combination dies. Just about everything in today’s print media market is open to sculptured embossing and foil stamping.

The creation process of making a sculptured embossing/combination die begins with the customer and designer discussing the project. Deciding what type of foil stamping and or embossing is required, what type of die and counterforce is required, shapes and textures within the designs, what type and thickness of substrate will be used. The overall look and feel, the finish, the areas where foil is to be printed, the print and or embossing run and so forth. All these and more will affect choices made in the CAD-CAM design, die material, engraving depth, whether hand finishing is required and so on.

Combination Work

Combination foiling and embossing, or foil embossing integrates foil stamping and embossing into one press pass through the use of a combination die, which is usually a Brass-sculptured Embossing Die.

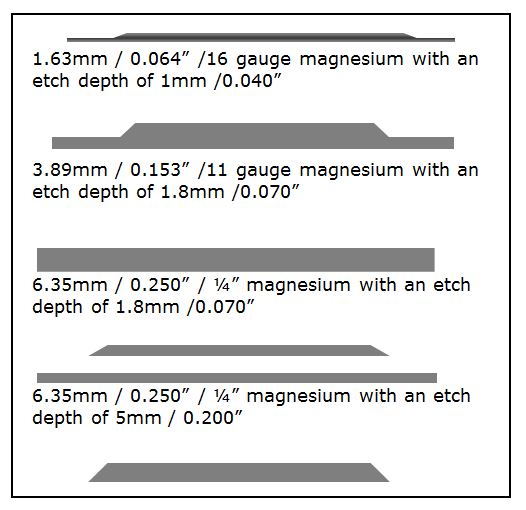

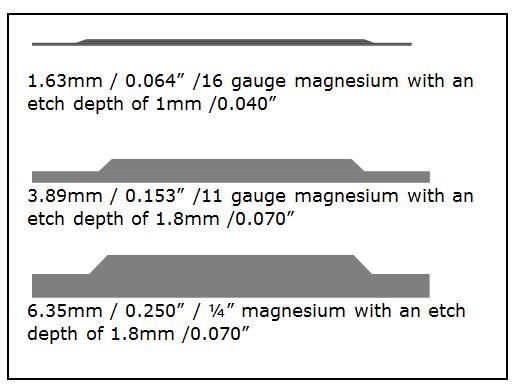

Magnesium

- Typically chemically etched but is also engraved as a cheaper alternative to Brass and Copper.

- Economical & versatile material.

- Ideal for short runs.

- Fast to produce when etched.

- Low cost material.

Material available in 1.63mm, 5mm, 6.35mm (¼”), 7mm thickness.

Brass

- Normally produced by CNC engraving but can be etched and is an alternative to Copper or Magnesium.

- When engraved, environmentally clean – no chemicals involved.

- Great for long runs.

- Excellent for printing and or embossing where precisely defined edges & shoulders are important.

- Fast production.

- Accurate reproduction of single or multiple images.

- Extremely durable.

- Material retains heat and has good heat transfer properties.

Material available in 3mm, 4mm, 5mm, 6.35mm (¼”), 7mm thickness.

Copper

- Chemically etched but is also engraved as an alternative to Brass or Magnesium.

- Ideal material for long print and or embossing runs.

- Ideal material for holding fine detail.

- Good for regularly repeating jobs.

- Extremely hard with good etching characteristics.

- Excellent for printing and or embossing where crisp sharp edges are important.

Material available in 1.63mm, 5.38mm, 6.35mm (¼”), 7mm

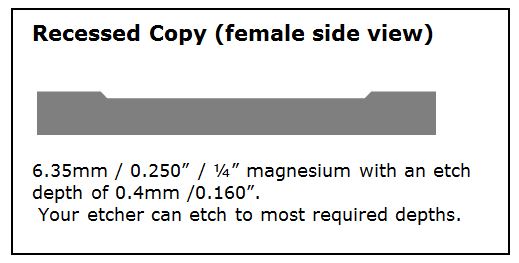

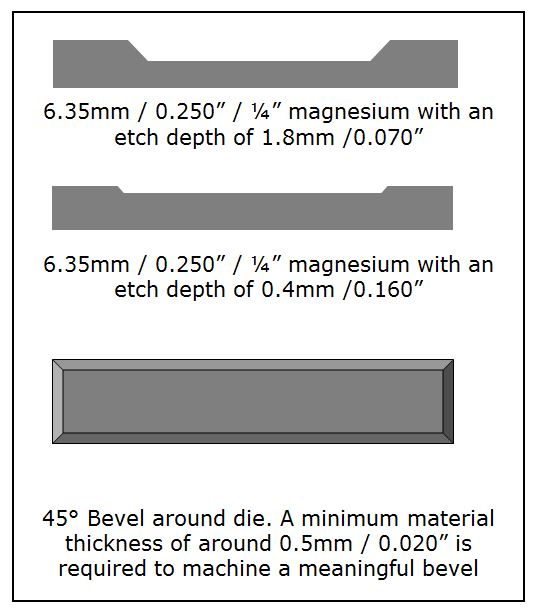

Magnesium

Relief (raised) copy (male cross section view)

Recessed Copy (female cross section view)

Bevels Regular

Hole Drilling

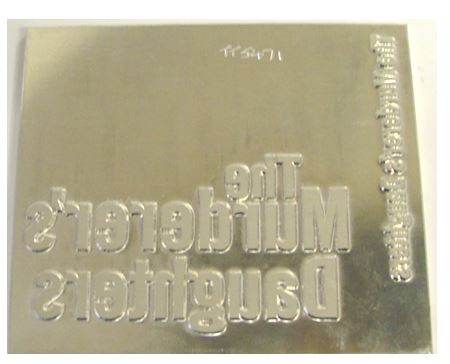

Foil Stamping Dies

Embossing Dies

De-bossing Dies

Membrane Overlay Embossing Dies

Use male-female embossing dies and counterforces to emboss keypads onto a polycarbonate or polyester substrate or hot stamp a corporate logo on a graphic overlay. The embossing die and counterforce can be metal – metal for long runs or metal – resin for short to medium runs.

Important points to remember:

There are hundreds of different types, textures, thickness, colours etc. of paper, card, plastic sheets and so forth and the manufacturers and paper merchants holding materials, samples and swatches of their product ranges. Ask for swatches, select the ones you require and ask for samples to test. Most samples are free so use that facility. Paper suppliers want you to use as many as possible of the different material they stock or can stock.

Artwork designers should always consult their printers and finishers concerning stock choices and designs. It is much easier for printers and finishers if they know in advance what they will be working with, so they select the best metal for the embossing die.

You should be able to create electronic foil printing and or embossing die files that are, faster and easier for your engraver and or etching company or department to process. However many have their own methods / processes for handling files, data and or orders, so it is extremely important to discuss the details of each project with your die maker to ensure that your files will achieve the results you require.